The materials used for the construction of fibre shafts are essentially three : carbon, Kewlar and fiberglass (different types).

Carbon is used for an extreme rigidity (undirectional graphite) or medium rigidity (carbon plotted).

Kewlar instead, thanks to its mechanical resistance, gives structure and body to the shaft.

Transparent Fiberglass is used as first and last layer as protection.

|

A fibre shaft is composed by different layers of kevlar fibres, woved and drenched of resin. These fibres are oven-baked in order to obtain a conic tube of one tenthed thickness.

The disposition of the material for position and quantity defines the technical features such as weight and rigidity.

Once you got the tube, it shall be adjusted, cutted to the right size and filled with polyurethane sponges in order to improve the acoustic during the game. After this operation, you have to apply the joint, the ferrule and the tip.

|

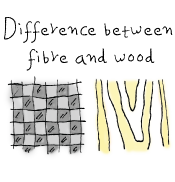

Even if fibre and wood are used for the same purpose, these two types of shafts are totally different from the structural and mechanical point of wiev. Even if fibre and wood are used for the same purpose, these two types of shafts are totally different from the structural and mechanical point of wiev.

A fibre shaft gives much more pressure to the ball than a wooden shaft even if the weight is the same.

The game is easier above all for 5 Skilles and other technical disciplines.

In a wooden shaft the force is distributed from the wood mass, in a fibre shaft instead, it is all propagated out of the shaft where there is the fibre. |

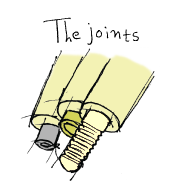

The Longoni joints range is built on two different kinds: VP2 or wooden joint (BJ or WJ). The wooden joint (used only in the carom game) is the classic one and allows a smooth game to the cue without changing the balance and the weight. The VP2 joint is more accurate and gives determination to the game, with a small frontal balance : it’s made of Titanium grade 5 ( the hardest ) or stainless steel in case weight is not an essential point. The female part of VP2 joint for the shafts is available in brass or in ergal (a special aluminium alloy) in order to balance in the best way cue and shaft: this choice is made by us directly according to the customer’s needs. On request you can order also cues with custom joints for other brands. The Longoni joints range is built on two different kinds: VP2 or wooden joint (BJ or WJ). The wooden joint (used only in the carom game) is the classic one and allows a smooth game to the cue without changing the balance and the weight. The VP2 joint is more accurate and gives determination to the game, with a small frontal balance : it’s made of Titanium grade 5 ( the hardest ) or stainless steel in case weight is not an essential point. The female part of VP2 joint for the shafts is available in brass or in ergal (a special aluminium alloy) in order to balance in the best way cue and shaft: this choice is made by us directly according to the customer’s needs. On request you can order also cues with custom joints for other brands. |

All Longoni shafts are covered by warranty for two years against manufacturing defects on parts such as joint, ferrule and ferrule sticking. The lamination process of Stratos shafts too is guaranteed for two years from the purchasing date. Each shaft is controlled before the shipment to be perfectly straight and to comply with the strictest requirements of our customers. In case of anomalies our widespread aftersale service will provide you with all the help you need.

|

Players of the Longoni team have an important role in the development of our shafts because it’s thanks to the skills of the best talents all over the world that we can create excellent shafts. All our models have been tested and approved by our champions in order to ensure the maximum results and satisfaction to our customers. Each profile and length has been developed to meet specific needs thanks to world champions such as Frèdéric Caudron, Semih Sayginer, Dick Jaspers, Marco Zanetti, Niels Feijen, Eddy Merckx, and all the other ones. The results speak for themselves: with our shafts the most important worldclass titles have been taken. Players of the Longoni team have an important role in the development of our shafts because it’s thanks to the skills of the best talents all over the world that we can create excellent shafts. All our models have been tested and approved by our champions in order to ensure the maximum results and satisfaction to our customers. Each profile and length has been developed to meet specific needs thanks to world champions such as Frèdéric Caudron, Semih Sayginer, Dick Jaspers, Marco Zanetti, Niels Feijen, Eddy Merckx, and all the other ones. The results speak for themselves: with our shafts the most important worldclass titles have been taken. |

|

The material is not enough: technology and experience is what is needed in order to work in the best way to obtain the most. The Longoni company is specialized in this and thanks to these competencies, it succeeded in diversifying the range of profiles available for its shafts range. Each discipline is followed in a specific way matching the experience reached in the others. For the carom game we have three possible different lenghts and conic or Eiffel profiles (similar to the shape of the famous Tour Eiffel in Paris), while in the pool you can choose four specific profiles. Each player has a wide range of shafts available among which he can choose shafts: more or less hard, longer or shorter according to his needs and type of game. |

On all the laminated shafts of the S2 / S3 Serie, we install the prestigious Japanese Black Kamui SS-OEM version, specifically produced for Longoni. On all the laminated shafts of the S2 / S3 Serie, we install the prestigious Japanese Black Kamui SS-OEM version, specifically produced for Longoni.

Thanks to this synergy our shafts have a great added value.

|

Longoni always cares to the environment. The raw material to produce cues and shafts is purchased only by qualified and specialized companies which also deal with the control of the forests. Glues and chemical materials are strictly regulated by the rigorous rules of the European Community to guarantee both the employees’ and the end users’ health. All the wastes are disposed of by companies specialized in compliance with the laws in force and the cut wood remains are used for heating purpose in the company during the winter season without having to use oil or gas that generate a lot of Co2. Longoni always cares to the environment. The raw material to produce cues and shafts is purchased only by qualified and specialized companies which also deal with the control of the forests. Glues and chemical materials are strictly regulated by the rigorous rules of the European Community to guarantee both the employees’ and the end users’ health. All the wastes are disposed of by companies specialized in compliance with the laws in force and the cut wood remains are used for heating purpose in the company during the winter season without having to use oil or gas that generate a lot of Co2. |

All shafts are lathed exclusively with CNC machines following very specific procedures in order to ensure uniformity and consistency to our customers. Before the shipment they are checked on test desks to control its straightness and the correct weight. All shafts are lathed exclusively with CNC machines following very specific procedures in order to ensure uniformity and consistency to our customers. Before the shipment they are checked on test desks to control its straightness and the correct weight.

The joint base is today further rectified by hand using a special tool to remove dirt and other production remaining. The perfection in your hands. |

All Longoni shafts, including the laminated ones, are entirely and uniquely produced in Italy in the factory based in Mariano Comense with techniques and machineries developed by us. Nothing is left to chance, but every single detail is well-finished, from the surrounding temperature to the density of the glues. The processing cycle of each shaft lasts at least 24 months: from when you cut the board to when it reaches the billiard tables around the world. The choice to continue completely producing in Italy was dictated by the desire to have a product different from all the other ones in terms of quality and technology, always under a strict control of our staff. All Longoni shafts, including the laminated ones, are entirely and uniquely produced in Italy in the factory based in Mariano Comense with techniques and machineries developed by us. Nothing is left to chance, but every single detail is well-finished, from the surrounding temperature to the density of the glues. The processing cycle of each shaft lasts at least 24 months: from when you cut the board to when it reaches the billiard tables around the world. The choice to continue completely producing in Italy was dictated by the desire to have a product different from all the other ones in terms of quality and technology, always under a strict control of our staff. |

|